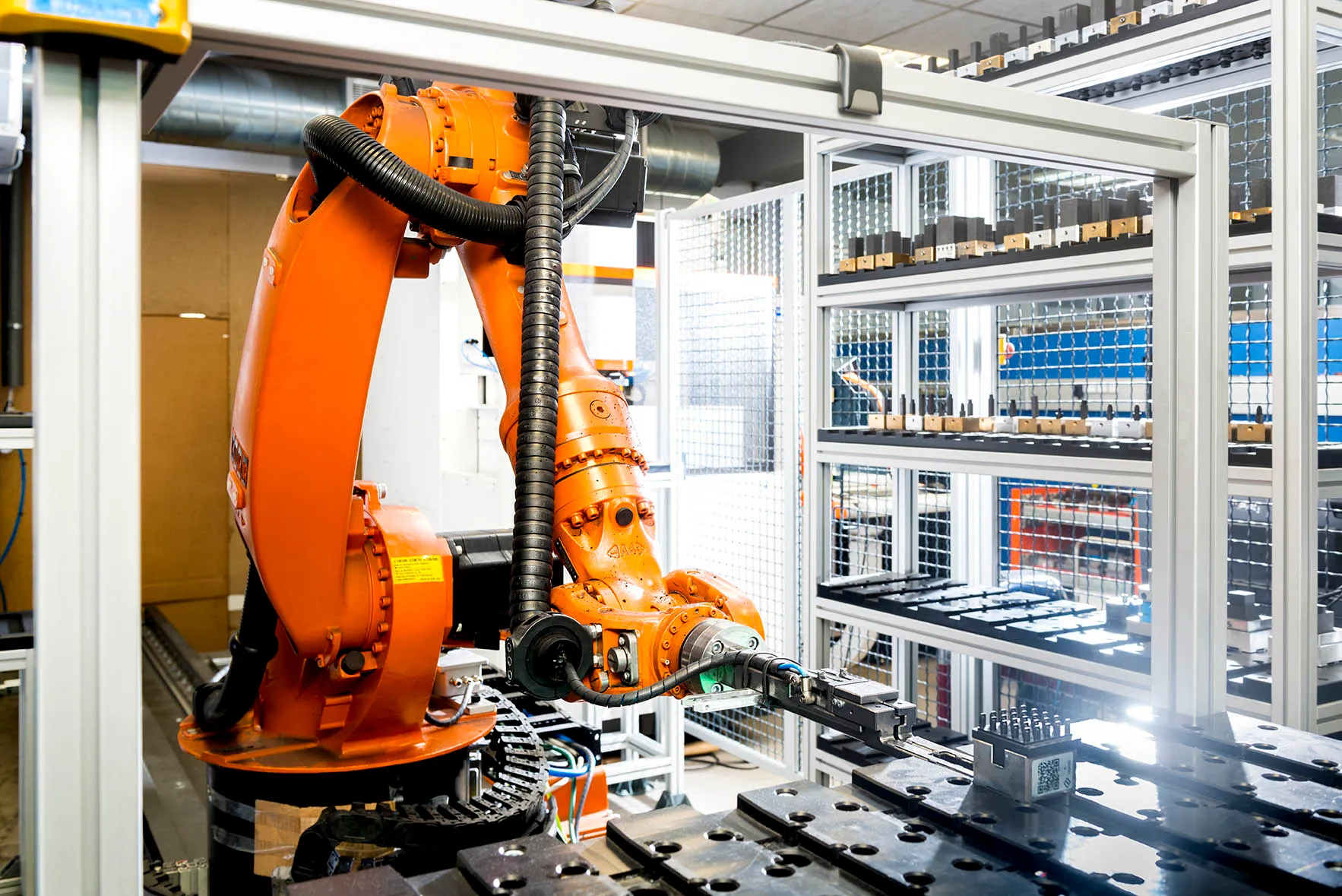

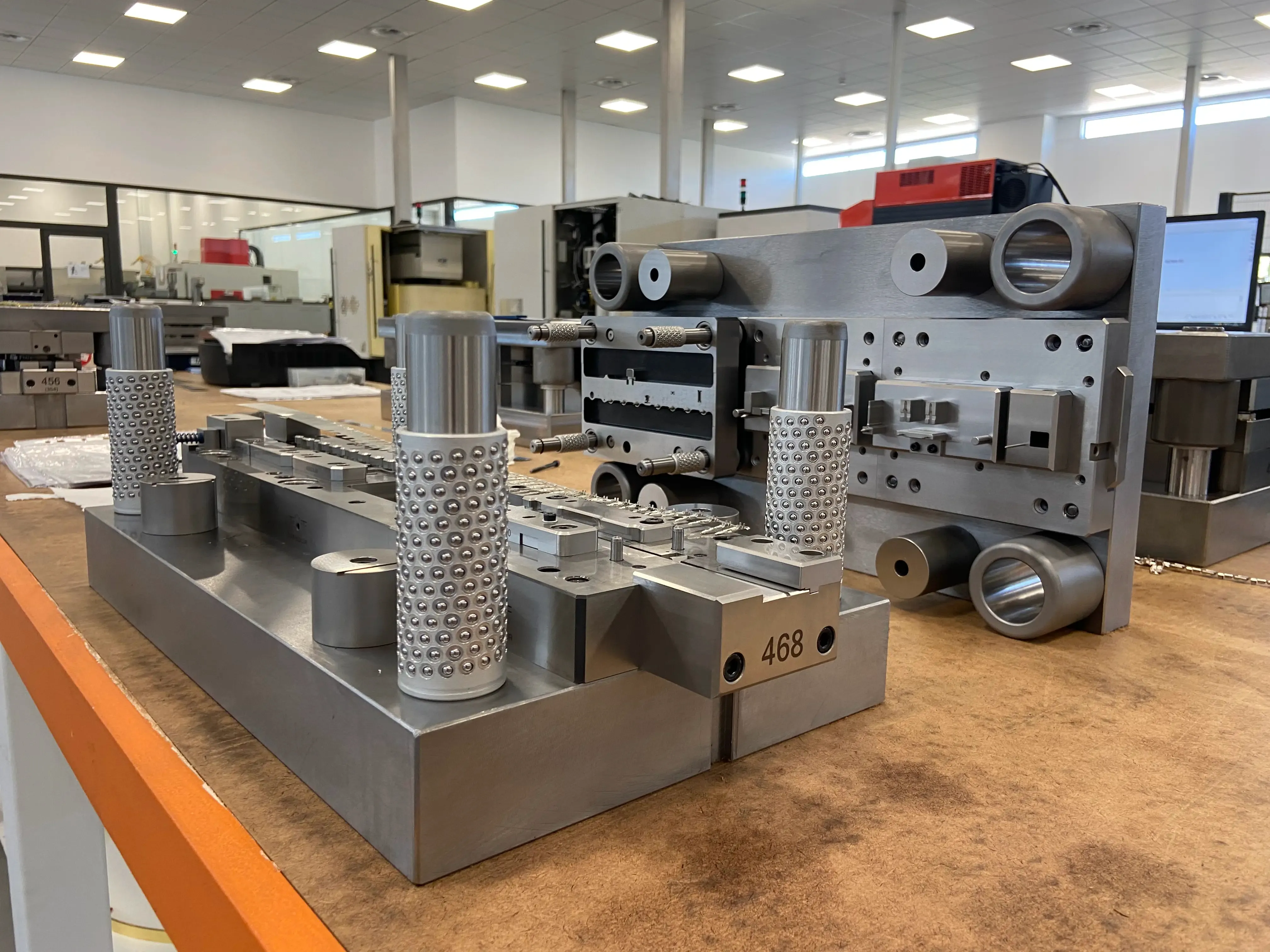

The tooling department is in charge of assembling and adjusting the moulds according to the technical specifications established by the product engineering department.

A highly qualified human team intervenes in this process, which has to respond to the technical problems that arise in each specific case, given the complexity and high quality requirements of Escubedo’s products.

We have a fully equipped high-speed press to carry out the necessary tests and adjustments to standardize the product and the mould before it is delivered to the production department.

Fully equipped mechanical workshop

Machining centers

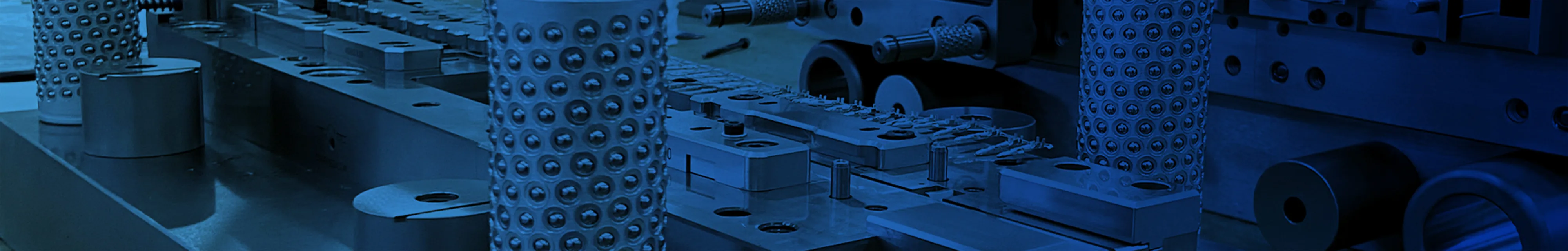

Wire cut and die sink EDM Machines fully robotized

Grinding workshop

Progressive dies and plastic injection tools assembly and maintenance workshop

Dedicated 50 tons press for rapid fine tuning of new tools

Complementing the R&D&O product team, the tool design team for progressive dies and plastic injection tools are capable of designing all the needed parts and tools to manufacture with the highest productivity and quality standards.

Finally the mechanical and tools workshop are in charge of manufacturing the parts and assembling the tools. Equipped with cutting-edge technology, our CAD workstations leverage Solidworks 3D with CAM software to power up high precision wire-cut and die sink electrical discharge machining, complemented by the efficiency of automated robotic support. Our commitment to precision extends to the use of top-notch metrology tools, ensuring the highest standards in product quality.

Escubedo offers comprehensive connection systems and solutions, encompassing product design through logistics and becoming a strategic partner beyond product design.

Optimal results are achieved through our highly skilled team and state-of-the-art production facilities.

Our connection systems meet the most rigorous quality standards, reaching any part of the world with personalized service.